hardness test scalew|different types of hardness test : service • International (ISO)• US standard (ASTM International) See more webNo feelings at all. These are very stupid spineless cowards who are carrying out an order and they have no empathy or heart. The man they hacked up was likely one of them who wudv been doing it to them had he been given the orders to do it and one of them had done something they shudnt have.

{plog:ftitle_list}

Twin Casino Brasil: Acesso Garantido para Jogadores Brasileiros; Como se Registrar no Twin Casino; Métodos de Pagamento: Facilidade e Segurança; Licença e Segurança: .

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use . See moreThe differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See moreThe Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See more

There are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more

typical rockwell hardness of materials

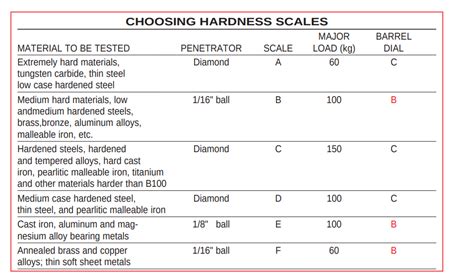

• International (ISO)• US standard (ASTM International) See more• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See moreASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.

Have you ever wondered what those mysterious numbers on a metal part mean? In this blog post, we'll dive into the fascinating world of hardness testing and explore the different scales used to measure a . The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, .

The Mohs scale of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material. The scale was introduced in 1812 by the German geologist and mineralogist Friedrich Mohs, in his book Versuch einer Elementar-Methode zur naturhistori.What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a .

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .

You can use the Rockwell hardness test to test the hardness of materials. You will use the Rockwell test to perform tests on metals ranging from thin steel all the way to harder metals like Titanium. However, there are .Superficial Scales. The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial .Correspondent relations among scale, indenter and test force: Hardness symbol Diameter of Indenter mm F/D2 Test force N/kgf HBW 10/3000 10 30 29420(3000) HBW 10/1500 10 15 14710(1500) HBW 10/1000 10 10 9807(1000) Brinell .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

The Knoop hardness test; Other hardness scales. Hardness scales may also refer to: Methods of measuring the deposit formation by hard water. The scale of Pencil hardness This page was last edited on 11 February 2022, at 22:38 (UTC). Text is .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. The Mohs Hardness Scale is used as a convenient way to help identify minerals. A mineral's hardness is a measure of its relative resistance to scratching, measured by scratching the mineral against another substance of known hardness on the Mohs Hardness Scale. . This method is especially useful for identifying minerals in the field because .

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; . it is a common process to convert one hardness scale to another. For this purpose, many . The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, mineralogy, and material science. The scale is qualitative, ranking minerals from 1 to 10, with 1 representing the softest mineral and 10 the hardest. The . The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation. Scale A uses a diamond cone indenter with a maximum pressure of 588.4N (60kgf); Scale B uses a 1.588mm (1/16 inch) steel ball indenter with a maximum .

Brinell hardness. The Brinell hardness scale is a widely accepted measure of hardness in materials. It involves pressing a ball of steel (or tungsten carbide for harder materials) into the test piece at a constant and known force. The softer the material, the deeper the ball will penetrate and vice versa. The next step is to take a measurement of the diameter .

Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the world’s leading materialographic and metallographic experts. . Our hardness testers for the Brinell scale .

Two inline skate wheels with different durometer – 85A and 83A Digital Shore hardness tester. The Shore durometer is a device for measuring the hardness of a material, typically of polymers. [1]Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials. Lower numbers indicate less resistance and softer materials. Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references .No wonder, Rockwell hardness testing scales are globally used and are the most popular ones. It is used for static hardness testing of the material. We have described thoroughly in this article the scales of the hardness test. Just .

water bottle brand ph test

water bottle brands test

The Mohs scale of mineral hardness is based on the ability of one natural sample of mineral to scratch another mineral visibly. The hardness of a material is measured against the scale by finding the hardest material that the given . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . The Rockwell hardness test is divided into various scales, each with a wide range of applications. (5) It is important to note that Rockwell hardness values obtained from different scales are not comparable. 4 .

There are several scales made for discussing different materials. The test is mainly utilized when the materials are too soft for the Rockwell test. Materials with a very soft texture, like rubber and TPE, should be tested with Shore D. There are three most popular Shore hardness scales:

The Shore A scale is a measure of the Shore A hardness of elastic materials such as rubber or soft plastics, and the Shore D scale is a measure of the Shore D hardness of hard plastics and rubbers. The dimensionless reading of the Shore A and D readings range between 0 and 100; where 0 represents complete penetration, and 100 represents no . The Mohs scale is only one of a number of scales used to assess mineral hardness. Others include the Vickers scale, Brinell scale, Rockwell scale, Meyer hardness test, and Knoop hardness test. While the Mohs test gauges hardness based on a scratch test, the Brinell and Vickers scales are based on how easily a material can be dented.

The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was chosen to .The ASTM specifies thirty different Rockwell scales, each employing a different combination of test forces and indenter types, which allows the testing Test Procedure of most types of metallic materials and products. When Rockwell hardness is called out by a product standard or specification, the choice of scale is usually specified. In situations where the user must choose .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

The Shore A hardness scale is a method used to characterize how resistant materials are to localized deformation or indentation. It is one of many scales used to measure the durometer (or hardness) of a material, typically of polymeric materials. . Manufacturers use durometer testing as a quality check for manufactured products. For example .

Each Rockwell hardness scale is identified by a letter designation indicative of the indenter type and the major and minor loads used for the test. The Rockwell hardness number is expressed as a combination of the measured numerical hardness value and the scale letter preceded by the letters, HR. . The Knoop hardness test method is one of . The Mohs hardness scale is the standard geologists and gemologists use to grade minerals and gemstones. They use the Mohs hardness test to determine "scratchability" of a material. So because diamond can scratch quartz, diamond is considered harder than quartz.

types of hardness testing methods

types of hardness testing machine

Resultado da Enviar link de grupos de cp niñas solo niñas

hardness test scalew|different types of hardness test